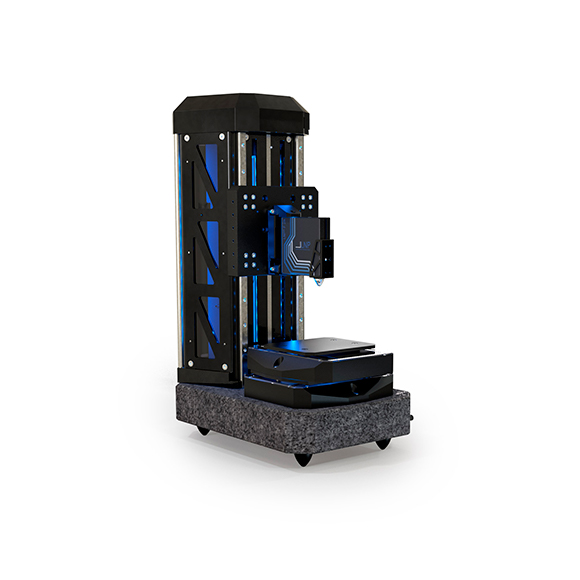

034137

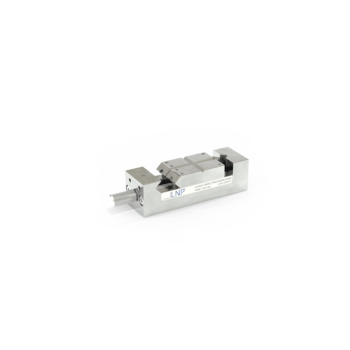

Order-Nr.: 034332

The workplace solution for standard test procedures according to:

ISO 48, DIN ISO 48, IRHD-M

Measurement at the push of a button! Hardness testing has never been so easy and accurate. Standard-compliant hardness determination for elastomers and plastics.

The product complies with the European Machinery Directive and is therefore CE compliant.